Waterjet Diamonds

Home / Waterjet Diamonds

Waterjet Diamonds

Index

Materials

Process

Quality

Products

Services

For over 80 years, our Company has been producing high precision technical parts in super-hard materials such as synthetic sapphire/ruby, hard metals and fine ceramics for industrial applications.

We are one of the few existing manufacturer producing UHP orifices in syngle crystal diamond used for water jet cutting, cleaning, de-burring, nano-tech. dispensers, to extremely small diameters starting at 15 microns size or over 6.000 bar of pressure.

We provide top quality, high precision items, with an evolved design developed throughout years of research. The increasing costs of downtime in the industry have created the need to have longer lasting, increasingly reliable parts. Diamond orifices lasts longer and promote longer life to the supporting equipment.

Our experience in this manufacturing process has brought us to develop the CARAT, Diamond Cutting Head; the concept is entirely new and adapted to modern hydro-abrasive cutting applications.

Quality control is the topic during every step of the production process, from the raw material selection in terms of finest stones to the crystal orientation ensuring the strongest and most resistant surface.

Our attention to every detail, is your guarantee of constant quality and precision.

Materials

It’s the hardest known material in nature: 10 times more than synthetic ruby / sapphire and uncomparable wear and fatigue resistance.

The growing demand of diamonds for industrial applications and the difficulty in obtaining constant quality concerning the natural product brings to a significant increase in costs of raw materials.

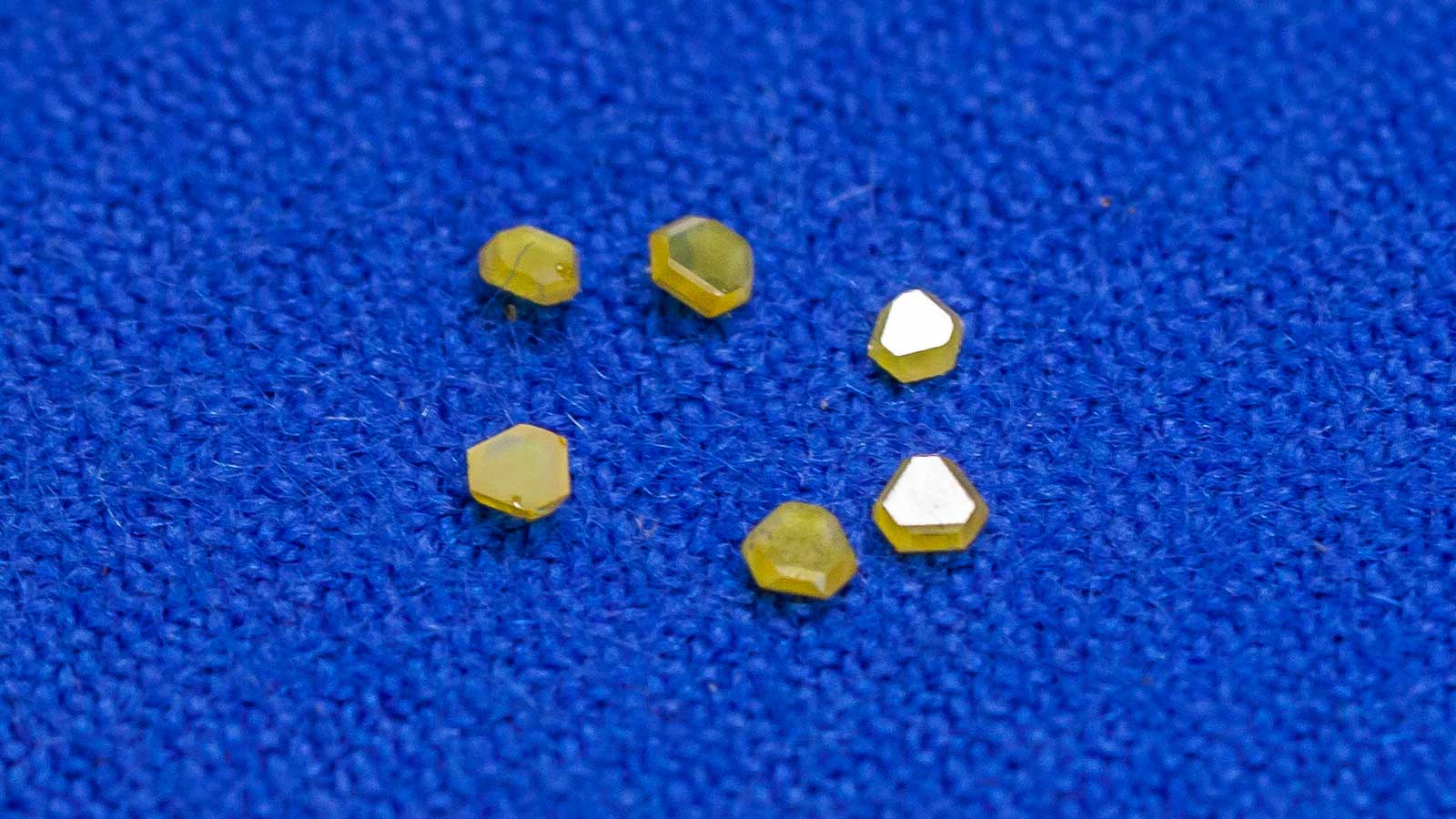

But during the last years the continue research has developed sophisticated synthetic products with high level consistent quality. Gardella, the only Italian manufacturer and one of the few in the world, is pleased to announce a new generation of diamond nozzles SSCD (Synthetic Single Crystal Diamond) with optical orientation of the crystal.

The most obvious advantages are in the structure of the diamond itself, devoid of inclusions and defects typical of the natural one and that leads to a consistency of quality and workability.

In practical terms related to crystal orientation in particular, ensures perfect distribution of tensions within the crystal and hence the maximum hardness and wear resistance.

Physical characteristics:

- Chemical composition: Carbon pure tetrahedral structure.

- Hardness: 10 Mohs (over 10,000 Vickers).

- Density: 3.51 to 3.55 g/cm ³.

- Toughness: 3.4 MN m-3/2.

- Refractive index: = 2.4174 to 2.4176 N.

- Refractivity: Monorifrangente.

- Color: Straw.

- Temp Combustion: 820°C.

- Temp Melting point: 3,500°C in a vacuum.

Process

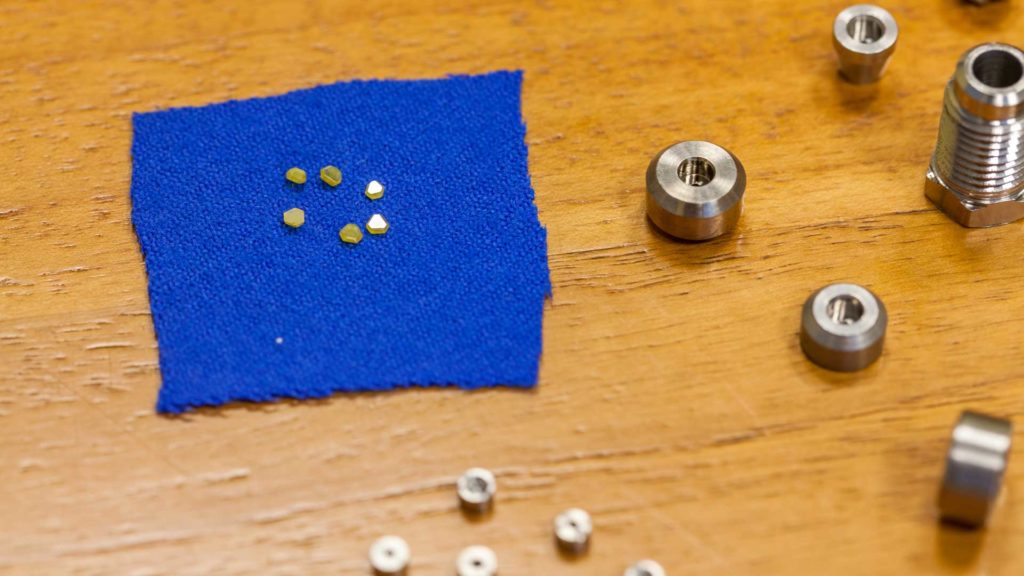

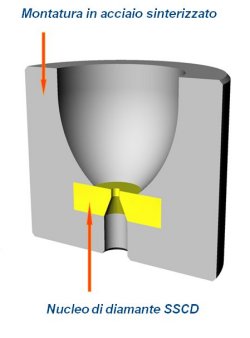

The core of the SSCD diamond is sintered in a special steel frame, with a specially developed process, based upon Gardella expertise.

The second step consists in the laser drilling of the diamond core, with a hole geometry very close to the final one.

Then the nozzle is polished with tools provided with increasingly fine diamond powder and finally polished to achieve perfect lapping of the hole.

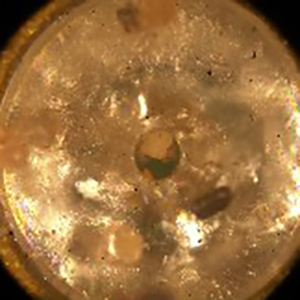

At this point all the SSCD diamond inserts are inspected at the microscope at 250 magnification and tested both in alignment and high pressure.

Quality

The special technique of diamond sintering grants the highest strength of the product during assembly and tightening phases and a higher resistance to mechanical stress.

In addition, the specific geometry and positioning of the core, prevents from any water leakage between metal and diamond, due to erosion of steel and the stress of high pressure cycles.

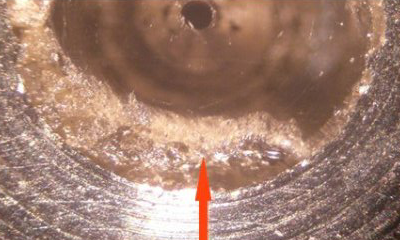

Typical erosion of the steel around the diamond, due to stress of high pressure cycles, due to infiltration of water going to disturb the jet beyond repair.

Diamond crack on the diameter of not-sintered diamond core, usually less resistant to mechanical stress, since the mounting seal ring.

All our diamond nozzles are subject to a strict set of dimensional checks, inspection visits and testing, to ensure the perfect product features to maximize performance.

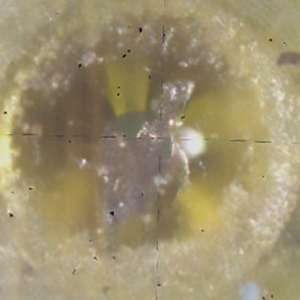

- Visual inspection at 250x.

- Orifice clogged with metal particle.

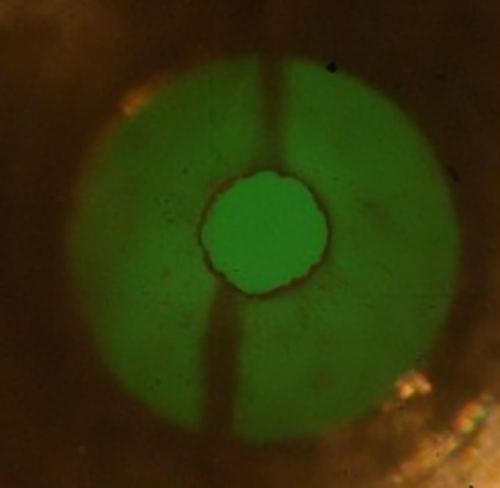

- Visual inspection at 250x.

- Orifice polluted with particles of abrasive.

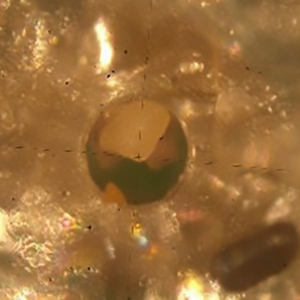

- Visual inspection at 250x.

- 40-µm new orifice hole.

Functional tests

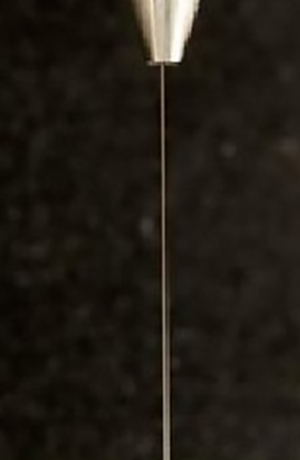

Coherent jet of pure water produced during HP testing of on SSCD cutting orifice.

Ø 0.12 mm – 3700 bar.

Un-coherent jet of pure water produced during HP testing of on SSCD cutting orifice.

Ø 0.15 mm – 3700 bar.

Perfectly aligned jet in alignment test with orifice SSCD hydro-abrasive cutting.

Ø 0,25 mm – 70 bar.

Misaligned jet during alignment test with orifice SSCD hydro-abrasive cutting.

Ø 0,25 mm – 70 bar.

Products

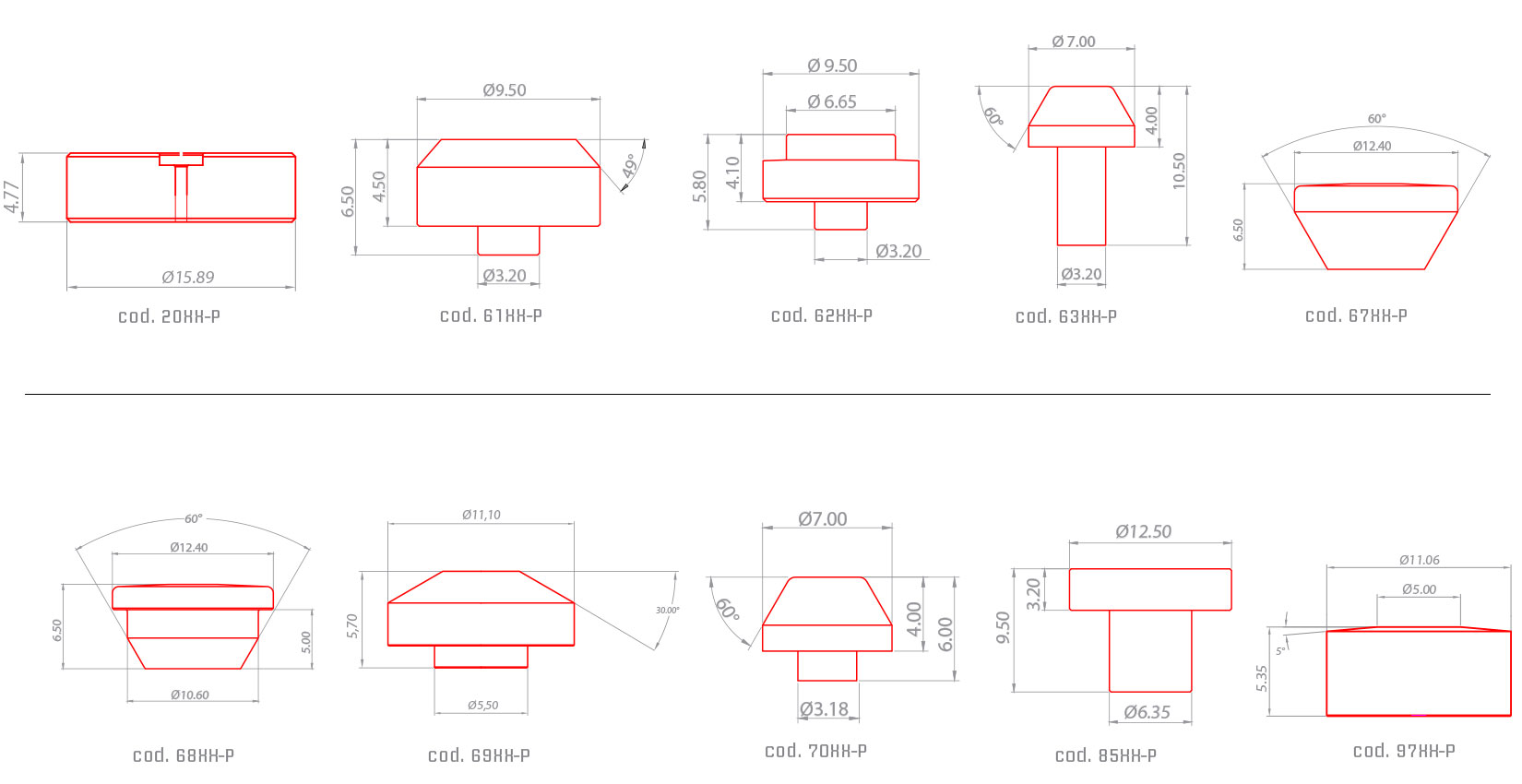

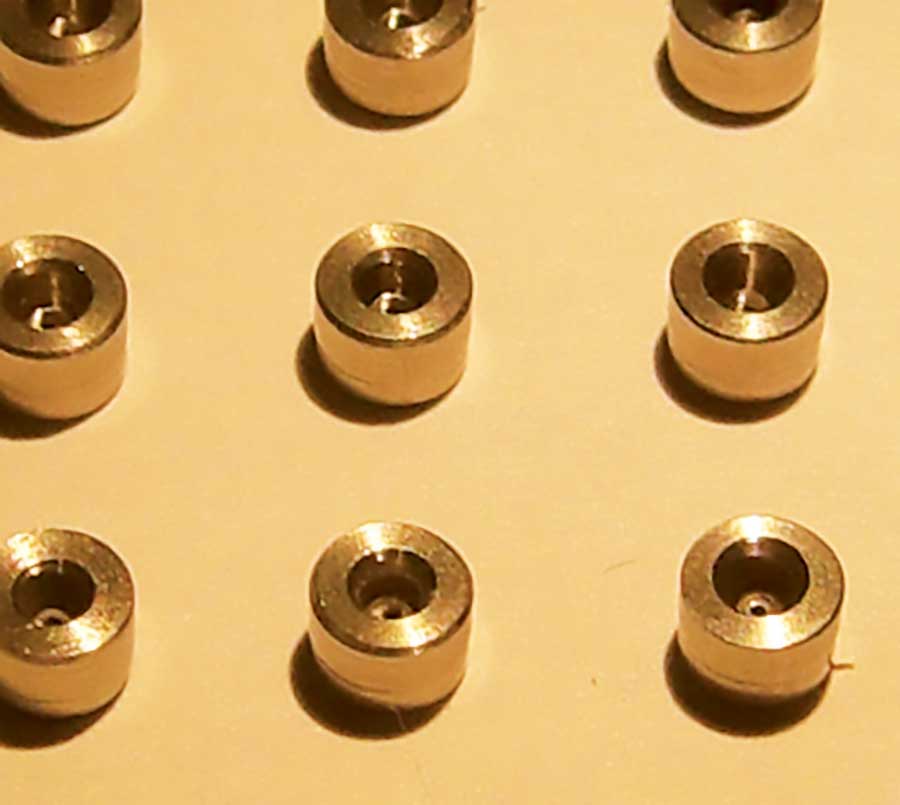

- SSCD diamond inserts.

- SSCD diamond orifices for water jet cutting systems.

- SSCD diamond nozzles for high and very high pressure surface cleaning.

- Carat Plus, hydro-abrasive cutting head with integrated and pre-aligned SSCD diamond orifice.

- SSCD diamond micro nozzles.

- Special nozzles design for high-pressure micronization and nano-technologies.

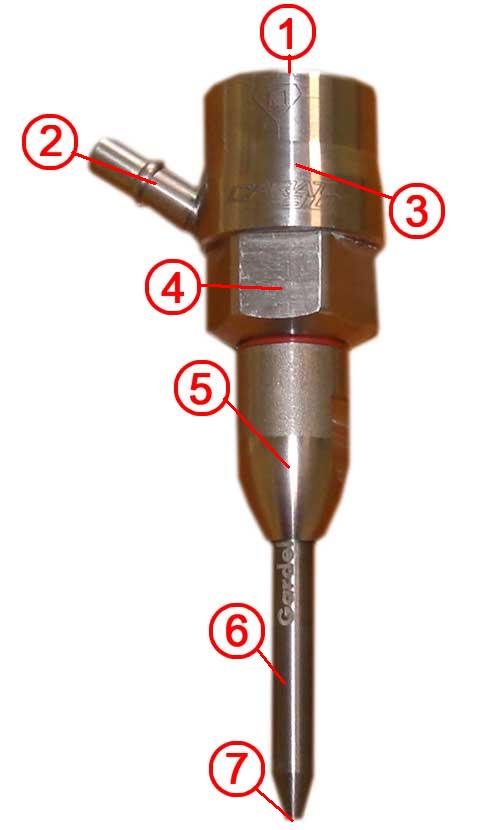

Carat Head 3.0

Integrated Diamond Head

The material used for the orifice is SSCD (Synthetic Single Crystal Diamond), diamond, the hardest material known. The wear resistance of the orifice is significantly superior to synthetic diamond and of course no comparison to sapphire and ruby orifices.

The water stream is ALWAYS aligned and maximizes the cutting performance and a correct wear of the abrasive nozzle. The result is an increase of the cutting speed and the service life of the abrasive nozzle improves up to 30 percent.

The unique features of the diamond together with the special CARAT design allows the maintenance of a coherent stream for a longer time with the best cutting power and performance. The abrasive flux is also increased and more regular.

CARAT cutting head was designed to be of reduced mass and easy to handle. It is composed of only three elements in addition to the abrasive nozzle which is the only interchangeable part.

This aspect substantially reduces the times due to replacement of wear parts and other critical components common to other more complex cutting heads.

The mixing chamber is realized using long-life carbide and it has a special design that reduce the internal turbolences.

Several adapter are available to make the Carat head compatible with the most diffuse waterjet systems on the market.

1. Filettatura 3/4”-16 UNF DX.

2. Il tubetto di adduzione abrasivo è inclinato di 40°, il che agevola ed incrementa la velocità delle particelle di abrasivo all’interno della camera di miscelazione. Il pezzo è smontabile e sostituibile una volta usurato.

3. L’orifizio è in diamante SSCD, il materiale più duro esistente ed ha una resistenza all’usura ed alla fatica meccanica non paragonabile allo zaffiro/rubino.

4. Camera di miscelazione realizzata in carburo di tungsteno LONG-LIFE.

5. Il serraggio sul focalizzatore avviene attraverso un pinzetta autocentrante che non presenta anelli o altri componenti. Il focalizzatore è l’unico particolare di usura che deve essere sostituito periodicamente.

6. Ugello focalizzatore realizzato in carburo di tungsteno LONG-LIFE.

7. Il perfetto allineamento del getto permette un’ottimizzazione del taglio ed un’usura uniforme dell’ugello focalizzatore. Ciò si traduce in un incremento della velocità di taglio e della durata del focalizzatore, che può arrivare fino al 30% in più.

Economical advantage of Carat head

Sapphire/Ruby

Estimated orifices quantity per year, per each cutting head: 50.

Approx cost €/p.: 11.

Estimated for of conventional cutting head: € 200.

Total cost per year: € 750.

Estimated time for orifice replacing: 10 minutes (0,15 h).

Number of orifices replacing per year: 50.

Total time necessary for ALL substitutions, in hours: 7,5 h.

Down time cost €/h: 100.

Estimated cost for down-time €: 750.

Total cost including materials and down time: € 1500

CARAT Head

Estimated orifices quantity per year, per each cutting head: 1.

Estimated cost including HP filter: € 750.

Total cost per year: € 750.

Estimated time for orifice replacing: 10 minutes (0,15 h).

Down time for cleaning / refurbishing of diamond: 1.

Total down time: 0,15 h.

Down time cost €/h: 100.

Estimated cost for down-time: € 15.

Economical advantage of Carat head € Total cost including materials and down time: € 785.

Services

We propose a control, revision and testing service for all diamond orifices, whatever size or brand.

Orifice Ø 0,18 mm dirty and plugged.

Orifice Ø 0,18 mm cleaned and re-polished.

Contact us

Please don’t hesitate to contact us for quotations.

You can call us at +39 0383 41575 (Monday-Friday: 08:30-12:30, 14:00-18:00), or you can fill this form and you’ll be contacted as soon as possible.